Auxiliary Driving System

-

Camera Controller Assembly Test Line Overview

Camera Controller Assembly Test Line OverviewThe equipment is configured with five workstations, and the core processes include: dispensing, PCBA feeder pre-assembly, screw fastening, air-tightness testing, EOL testing, and camera module assembly. The entire cycle time is 32 seconds.

The equipment is designed as an integrated modular system

The equipment is designed to permit the easy relocation, addition, or replacement of modules

The screw driving process can detect screw length, monitor torque, angle, and floating height

The entire line can switch programs with a single button press

-

Binocular Camera Assembly Test Line

Binocular Camera Assembly Test LineThe equipment is equipped with 6 stations, the core process includes: MTF test, screw attached, lighting test, EOL test and camera module assembly process, the whole beat 22S.

The equipment is designed as an integrated modular system

The screwdriver bit supports quick changeover, with a changeover time of less than 1 minute

The entire line can switch programs with a single button press

-

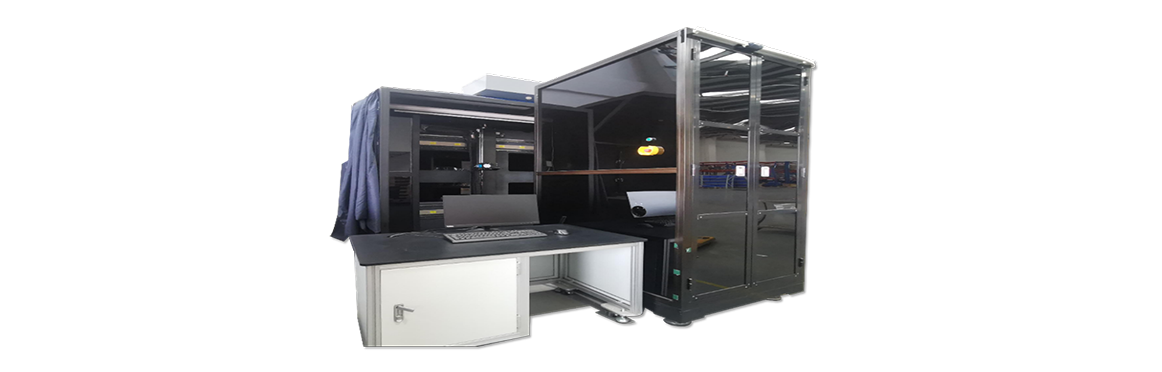

Lidar Test Equipment

Lidar Test EquipmentTBP-U100 series test system uses laser beam to image on the frosted mirror and captures the imaging spot through the CCD lens to calculate the distance between the laser source and the imaging surface and the relative position of the platform and the error accuracy of the sensor.

Laser deflection angle detection

With the rotation axis, it can detect 8 laser surface

Test accuracy: X direction: 0.204°and Y direction: 0.014°