Flat Panel Display

The world's leading supplier of flat display touch panel testing equipment

Products include display, touch, signal, optics, reliability drive, testing, screening, compensation and repair functions for LCD/OLED and new generation micro display (Micro OLED, Mini LED) production processes. Independently developed products have achieved breakthroughs in core technology and provide turnkey solutions for domestic and overseas high-end smart phones, tablets, vehicle display panel manufacturers and other customers.

-

LCD/OLED

LCD/OLED module testing equipment

-

New Generation Micro Display

Micro display(Micro OLED/LED、Mini LED)module testing equipment

-

Reliability and Aging

Reliability and aging testing equipment

Features and Advantages

The products have the advantages of high precision, fast speed, and no contact, overcoming the disadvantages of manual operation, and effectively reducing the production cost of panel manufacturers while improving the product yield of panel manufacturers, which has been highly recognized by customers. It has established long-term and stable cooperative relations with world-class brand manufacturers, and has become the designated partner of leading customers in the global smart phone industry and flat panel display industry.

-

Technology

TechnologyProvide a turnkey solution through multi-disciplinary cross-interaction and independent integrated testing platform

-

Products

ProductsVarious product lines covering manual, standalone and whole line testing requirements

-

NPI

NPIAn efficient and independent NPI team to meet customers' testing requirements from R&D design to product testing

-

Service

ServiceA delivery team of over 200 staff and a rapid response mechanism to achieve rapid on-site response to domestic and overseas major customers

-

-

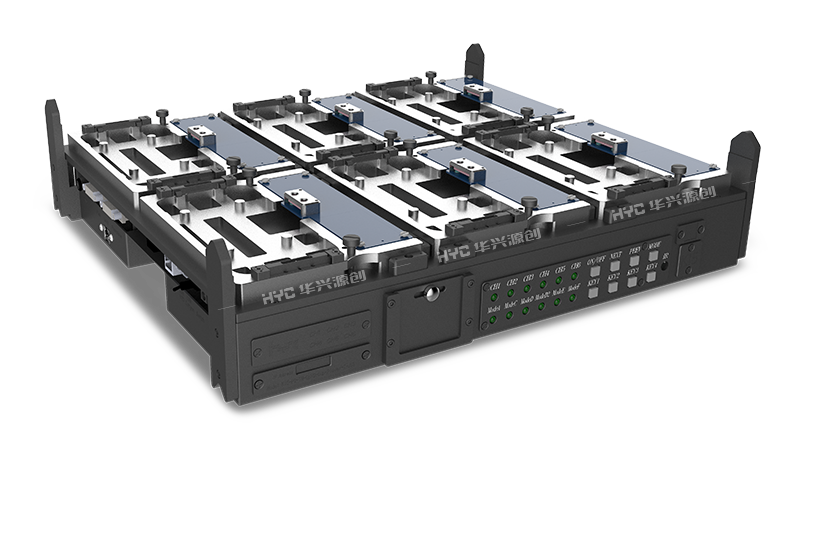

LCD/OLED Touch Senser Panel Testing Equipment

- LCD/OLED Module Touch Function Testing Equipment

- Multi-touch simulation, high stability

- Strong adaptability, work with different carriers, quickly complete the switch

- International mobile phone leading enterprise designated products

-

LCD/OLED Reliability Tester

- Display drive and touch register tester

- Wide suitability (90%RH, 65℃;85%RH, 85℃)

- Maximum 6 channels simultaneous test

- Designated products of international leading mobile phone enterprises

-

-

-

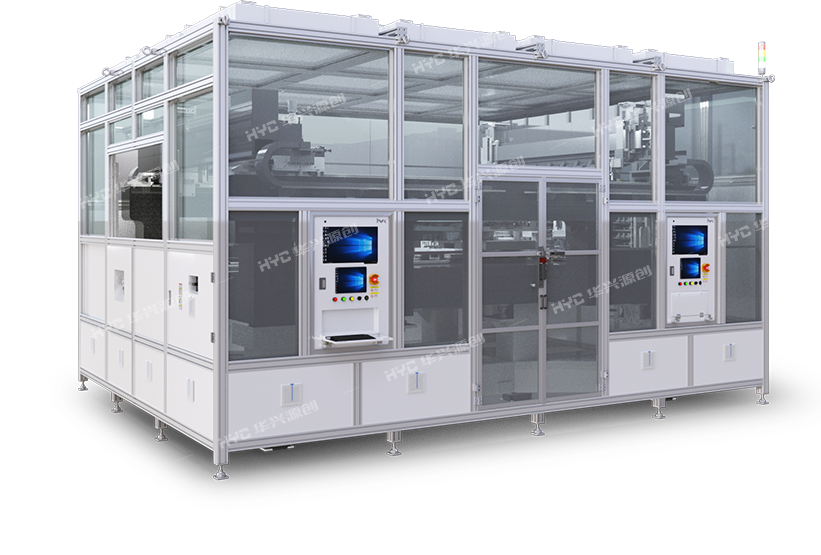

OLED Substrate Level Touch Testing Equipment

- OLED 6.5 gen line On-Cell flexible touch panel Half Glass Circuit testing

- Super large automatic equipment combine detection and aging repair function as one unit

- Comprehensive detection rate: 97%

- MAX size of product can be inspected

1500mm x 925mm (2 pcs)

-

OLED Micro Crack AOI Equipment

- GDS crack AOI equipment

- Crack detection of inner and outer arc and hole area

- Capillary crack detection accuracy: 0.5μm

- MAX size of product can be inspected

390mm×185mm (2 pcs)

-

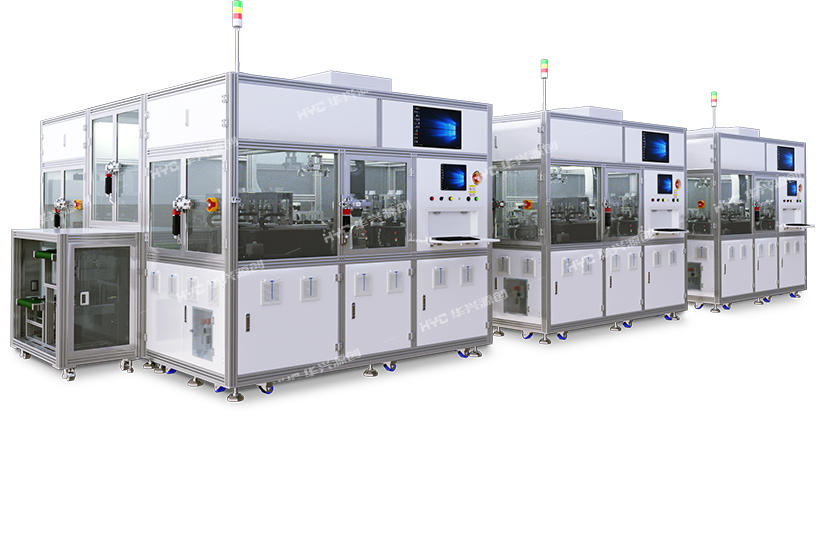

OLED De-Mura Automatic Testing Equipment

- OLED De-Mura Automatic Equipment

- Advanced sub-pixel-level optical imaging techniques and software algorithms Mura striae elimination

- Tact time (cycle time): ≤ 4.5s

- MAX size of product can be inspected

360mm x 250mm (2 pcs)

-

OLED Image Defect Testing Equipment

- OLED image defect automatic testing equipment

- Advanced sub-pixel level optical imaging technology and layered detection technology to achieve the detection of image defects

- Image defect detection rate above 99.5%

- MAX size of product can be inspected

360mm x 250mm (2 pcs)

-

OLED Image Chroma Defect Testing Equipment

- OLED image chroma defect automatic testing Equipment

- Refocusing optical imaging technology can detect chromaticity defects

- Image defect detection rate above 99.5%

- MAX size of product can be inspected

360mm x 250mm (2 pcs)

-

OLED Touch Function Automatic Testing Equipment

- OLED Product touch automatic testing equipment

- High-precision crimping mechanism and high-speed response loop to achieve detection of touch loop

- MAX size of product can be inspected

210mm x 110mm (2 pcs)

-

-

-

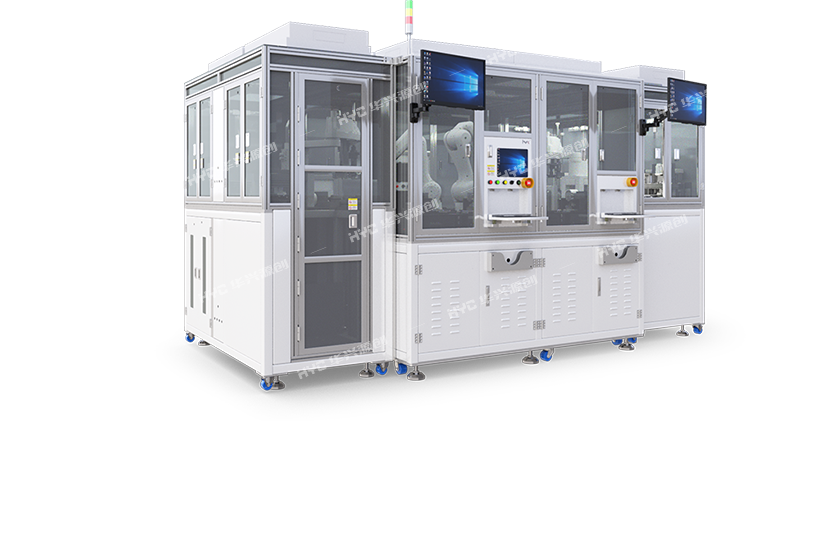

Micro OLED Display Testing Equipment

- Industry leading Micro OLED electrical performance testing equipment

- 8 stations, UPH=180

- Breakthroughs in core technologies

- The product was designated by two industry leading enterprises

-

Micro OLED Display Testing Equipment

- Industry leading Gamma+De-Mura automatic testing solution

- Convenient flexibility can be used individually or in combination

- 100% cleanliness

- The product was designated by two industry leading enterprises

-

-

-

Vehicle LCD Diplay Black Mura Testing Equipment

- Combine high-precision imaging brightness display technology and software algorithm to detect multi-gray level brightness and multi-angle color spot defects

- Compliance with European passenger vehicle testing standards©German Automotive OEM Work Group Displays

- MAX size of product can be tested

700mm x 150mm (2 pcs)

-

Aging Chamber

- Visual high temperature test equipment

- The reliability test can be achieved under extremely wide temperature range and extremely high control accuracy

- Temperature control range: +40℃ ~+70℃, Temperature fluctuations: 0.2℃

- MAX size of product can be tested

5. 5inch (3520 pcs)

-

-

-

Pattern Generator

- Supports screen detection with 8K resolution and above

- Maximum output bandwidth: 250Gbps

- It has 5G wireless communication and supports remote operation

-

Pattern Generator

- All parts are made in China

- Multiport output (MIPI/LVDS/eDP)

- Cabinet modelling

- 6 voltage outputs

-

-

-

3D Light Field Camera

- Domestic leading light field of 3D detection equipment

- Single shot, multiple aggregation, multiple angles, three dimensional imaging

- Accuracy: 8-16μm

- Z axis micron level resolution

- Macro vision, quickly resolve Z direction defect location problems

-

Color Analyzer

- Measure the chroma, brightness and scintillation of LCD Module

- High precision, high speed, convenient system integration

- Follow CIE1931 eye characteristic curve

- Breakthroughs in core technologies

-

Imaging Colorimeter

- Resolution 12M-151M

- CMOS sensor design based on science grade

- Flat panel display De-mura

- Breakthroughs in core technologies

-