Controller

-

BMS Fully Automatic Test Production Line

BMS Fully Automatic Test Production LineThe whole production line has 12 stations, mainly including ICT test, FCT test, EOL test, aging test, pressure resistance test, CCD test and other processes.

The whole line transmission adopts the design of upper and lower reflux. The two groups of main lines use modular belt lines through the two ends of the equipment. The tray size is 320mm * 320mm (the designed lift designs the transmission line body at the bottom of the equipment) and the transmission line interaction to realize the whole line cycle

Equipped with standard jacking movement and stop device

Optional RFID traceability system, RFID traceability system can identify fixture error prevention, information traceability, etc

-

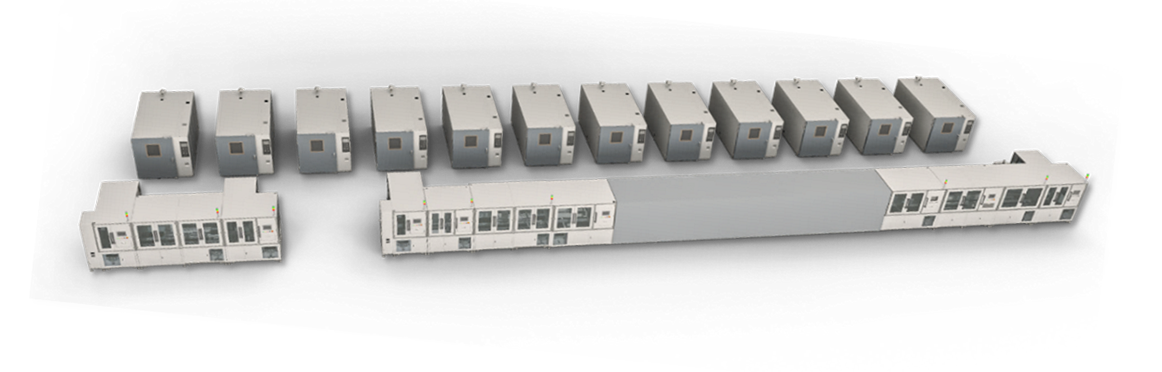

Powertrain and Chassis Domain Controller Production Line

Powertrain and Chassis Domain Controller Production LineThe production line has 12 sets of equipment, linear layout, upper and lower line tray circulation. The core process includes: lower shell & PCBA dispensing, top cover screw lock, laser marking & detection, EOL test, PIN needle detection, air tightness test, etc.

The production line layout is modular, each equipment is independently splicing, highly flexible and convenient for the integration and transformation of equipment in the later stage

Automatic assembly and detection line body to minimize the personnel allocation requirements and greatly reduce the personnel dependence

The production rate of good products in the production line is 99.5%, with MES data control of the whole line, real-time monitoring of product process data, and real-time alarm feedback of abnormal situations