Thermal Management System

-

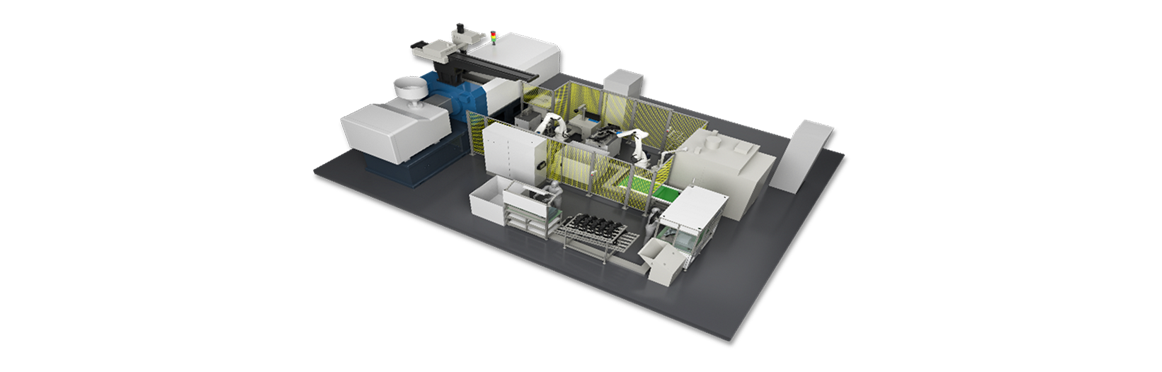

Thermal Management Water Tank Production Equipment

Thermal Management Water Tank Production EquipmentThe production line consists of 6 workstations, primarily including: steel sleeve feeding & pressing, laser marking on the tank body, hot plate welding of upper and lower tank parts, sealing ring & pump assembly, and EOL & air-tightness testing.

The production line utilizes two 6-axis robots for the transfer of tank bodies. Both the robot end-effectors and the station fixtures feature quick-change designs to enable flexible production of multiple products

The entire line is equipped with a MES, which allows for real-time monitoring through barcode scanning at each station, uploading data accordingly

-

The Thermal Management Controller Production Line

The Thermal Management Controller Production LineThe desktop dispensing machine equipped with a high-precision single-component screw valve can draw points, lines, arcs, and irregular shapes.

With a servo motor and lead screw drive, the repeatability accuracy of the device's position can be achieved to ±0.01mm

Driven by a motion control card, it can achieve various trajectory paths in three-dimensional space

Equipped with a high-resolution 20 million pixel camera for inspecting the dispensing trajectory, ensuring the accuracy of the dispensing process

A single-component high-precision screw valve, with high dispensing accuracy, can achieve a dispensing weight precision of ±2%